The perfect inventory solution for your company.

Inventory Module

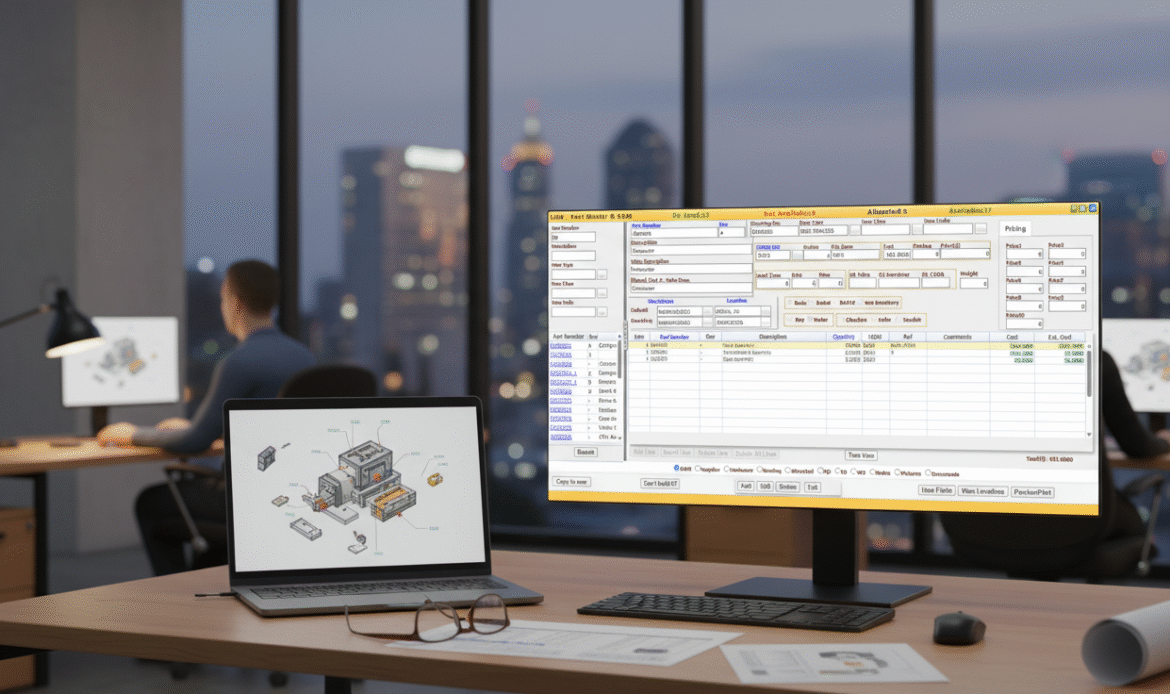

AMICS

The AMICS Inventory Module Software is the core module where part numbers are created and other essential information is added. This module can be used as a standalone solution, including screens for adding and subtracting inventory. Sample reports include “Inventory by location,” “Inventory Value,” “Transaction Log Report,” and more. Some of the screen shots are given below.

KEY CAPABILITIES

Part Master

Easily assign part numbers (up to 50 characters). In addition, you can:

Maintain bill of materials or BOM

Maintain Supplier Catalog Numbers

Maintain Customer Numbers

Add Operational Steps

Allocate Inventory

View Purchase Orders, Sales Orders and Work Orders

Maintain Pictures and Documents

Maintain Quality and other Notes

View Inventory including lot and serial numbers

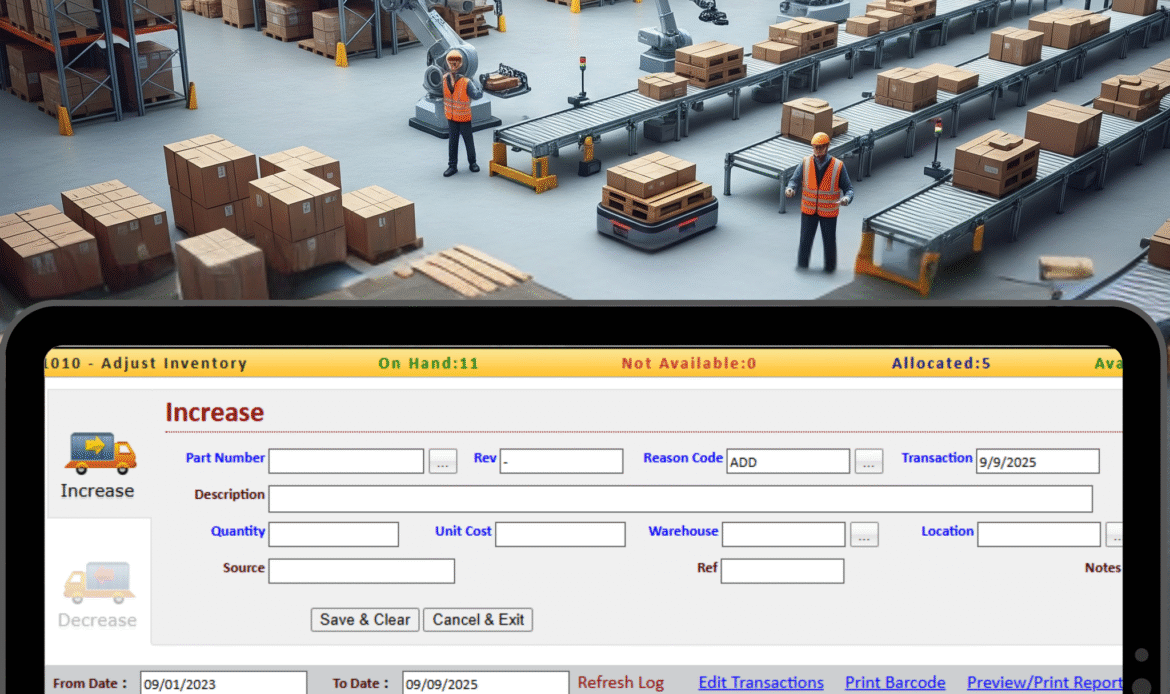

Adjust Inventory

Easily receive and pick inventory. Receive consignment, GFE, and other parts from customers or from any source. Consequently, you can adjust inventory and keep track of it precisely.

Receive consignment, GFE and other parts from customers or from any source

Adjust inventory and keep track of inventory

Add Source, Reference and notes on receipt

Print Bar Code Label

Track History

Output history transactions to MS Excel & PDF

Pick Inventory

Print Reports

Serial, Batch Lot Inventory

Serial Inventory

Receive serial numbers with ease. Add tag and Model information. Use bar code readers to receive quickly and accurately. Specifically, the system includes error checking during receipt for duplicates.

Add tag and Model information

Use bar code readers to receive quickly and accurately

Error checking during receipt for duplicates

History of transactions

Parts Traceability

Run reports

Export to excel

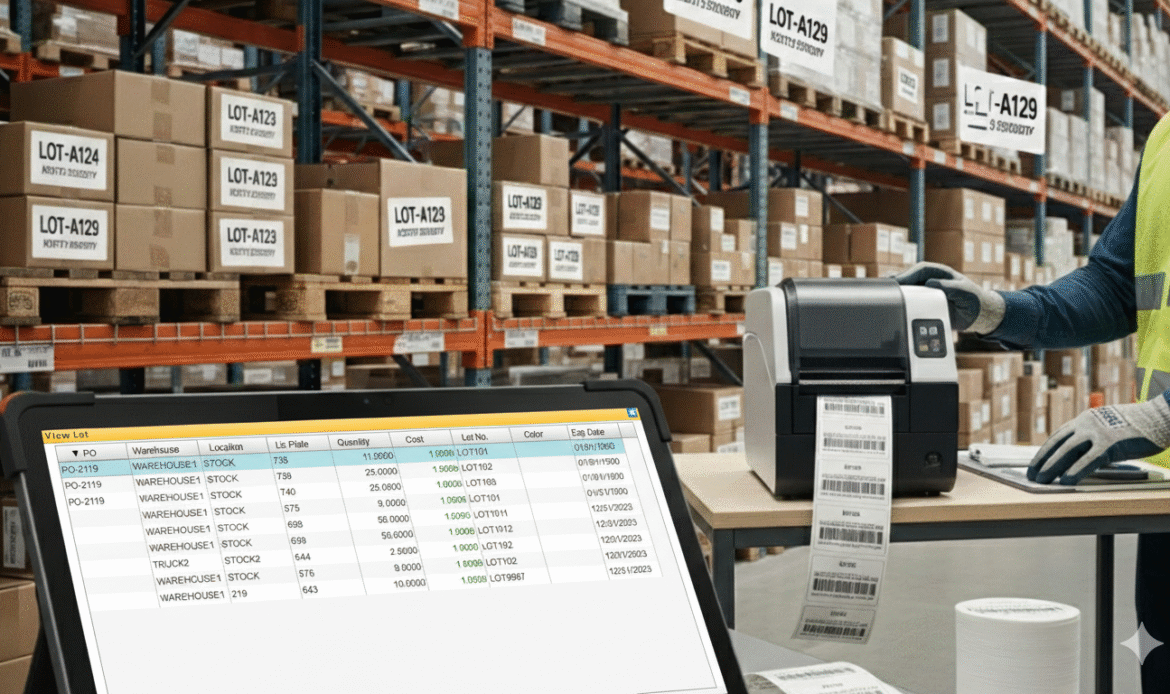

Batch and Lot

Easily receive and pick inventory. Receive consignment, GFE, and other parts from customers or from any source. Moreover, the Inventory Module Software allows you to adjust inventory and keep track of it.

Receive consignment, GFE and other parts from customers or from any source

Adjust inventory and keep track of inventory

Add Source, Reference and notes on receipt

Print Bar Code Label

Track History

Output history transactions to MS Excel

Pick Inventory

Print Reports

Batch Lot Inventory

As a result, AMICS is the trusted partner for warehousing, manufacturing, and government agency companies that want to optimize operations, improve customer satisfaction, and stay competitive in a demanding market. Ready to optimize your operations? Contact us today to schedule a demo.